B737 Maintenance Tail Dock

B737 Maintenance Tail Dock

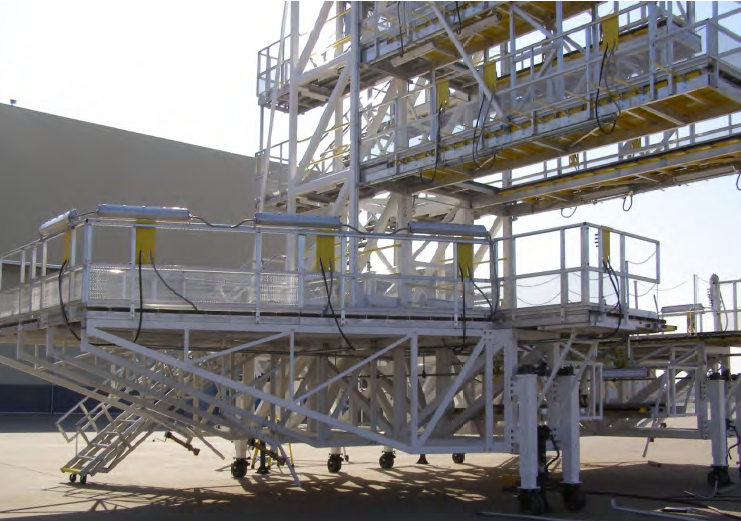

Our Boeing 737 Maintenance Tail Dock provides complete access to vertical and horizontal stabilizers, the APU cavity, and AFT fuselage areas. Maintenance on this area is critical and our aircraft tail stand offers enhanced worker safety for routine inspection, modification, overhaul, and repair of the aircraft empennage.

***Please be aware that all prices do NOT include freight. We have had to disable our online checkout feature because most of our products are too large to automatically calculate the freight, and need to be run manually. Please contact us via phone at 877-324-9990 or email us at sales@industrial-platforms.com with your ship to zip code for a complete quote including your freight cost.

B737 Maintenance Tail Dock

Our B737 Maintenance Tail Dock takes a modular stand set approach with options of steel or steel and aluminum construction combination. Our technology results in a very mobile, light weight, yet durable maintenance platform-proven in both the Commercial Aviation Aircraft Maintenance and U.S. Military MRO sectors. All design and fabrication of stands meet or exceed OSHA Fall Protection Standards. We can also build these tail docks in conjunction with wing stands or nose docks.

The aircraft maintenance platforms are generally comprised of left-hand (LH) and right-hand (RH) sub-assembly half-docks. Each half-dock consists of a main deck (stabilizer platform) located below three upper-platform catwalk areas, depending on aircraft type and maintenance work being done.

Features:

| • Leveling and stabilizing jacks | |

| • OSHA compliant guardrails and toe-boards | |

| • Designed-for-purpose non-slip decking on platforms | |

| • Heavy duty 12” swivel casters with brakes and swivel locks | |

| • Articulating stairways ultimately self-adjusting for height differentials | |

| • Sliders allow for contouring to the profile of aircraft tail due to variations of stand placement. | |

| • Adjustable sliding deck sections with non-marking protective rubber bumper along slider edges | |

| • Pricing includes: Design, Engineering, Manufacturing/Fabrication, On-Site Installation/Training,COTS Operations Manual. |

Benefits:

|

Articulating Stairs: Fall Prevention: Platform Height Adjustability: Tool Trays: Finish: Documentation: |

Options:

All options provided at every level |

|

| Optional air and electrical utility stations | Optional lighting |

Installation Pricing:

Within the Continental US contact for pricing |

Includes On-Site Installation per set at USA locations (approx. 40-45 days). This price includes labor, material, equipment rental, travel, lodging) Install figure includes final assembly, operator training and comprehensive technical manual. |

Canada contact for pricing |

On-Site Installation per set at specified locations (approx. 40-45 days) Includes labor, material, equipment rental, lodging, flight not included) Install figure includes final assembly, operator training and comprehensive technical manual. |

|

Non-North American Countries |

•1 x Experience Senior assembly technician •(Assumed project duration 40-45 days) •1 x Design engineer (intermittently as required) •All living and subsistence expenses included •Any specialist tools required •Our crew will have their own rental vehicle •Exceptionally expensive locations will require an additional consideration We suggest that each specific client be responsible for the provision of local labor, we can provide a schedule of what will be required in terms of head count and equipment. In this way the installation cost which otherwise would be greatly inflated by the inclusion of airline tickets, additional expenses and insurance can be avoided. This approach has the advantage of making the installation cost more in-line with local rates in lower cost economies, or the customer may opt to provide their own labor. For tail docks typically we will require rental or use of a 30-50 ton mobile jib crane for and driver, a telescopic forklift, small conventional forklift & at least 1 boom lift. We estimate a crew of between 4 & 5 relatively experienced steel erectors with a reasonable command of English or a capable translator. The crane will not be required for the duration, however the other access and lifting equipment will be. The local install crew should have their own tools, which is typical for a steel erecting crew. |

This maintenance platforms are for use during all aspects of aircraft maintenance, including aircraft jacking operations. Each half-dock can be adjusted in height. Similarly the main deck can be height adjustable independent of the overall height of each half-dock to follow the contour of the horizontal stabilizer of the aircraft.

Fabrication Authorities International, LLC. is dedicated to developing the most innovative aircraft tail maintenance stands through research, engineering, manufacturing, and marketing of the finest materials available. All of our products may be modified or completely custom designed to suit your needs. We offer a Custom Aircraft Maintenance Tail Dock, custom-built per order to satisfy all of your tail dock maintenance needs. These Tail Docks are constructed from the highest quality aluminum or steel. Contact us for a professional consultation with our aviation sales technicians today!

Please call for additional options or custom designs.

Fabrication Authorities International, LLC. Is your new “total access” solution.

We can customize most Industrial Maintenance Platforms to your specific needs.

Please call (877) 324-9990 or (727) 324-4620

Email us at sales@industrial-platforms.com