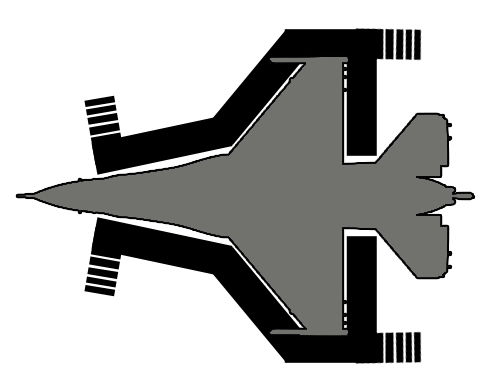

F-35 Wrap Around Maintenance Stand

F-35 Wrap Around Maintenance Stand

These full set wrap around stands are perfect for inspection, repair or daily phase maintenance of the Lockheed Martin F-35 AND F-16 Fighter Jets. Custom available.

***Please be aware that all prices do NOT include freight.***

We have had to disable our online checkout feature because most of our products are too large to automatically calculate the freight and need to be run manually. Please contact us via phone at 877-324-9990 or email us at sales@industrial-platforms.com with your ship to zip code for a complete quote including your freight cost.

F-35 Wrap Around Maintenance Stand

Model # FAI-F35-S-01

The Lockheed Martin F-35 is a single-seat, single-engine, fifth-generation multi-role fighter developed to perform ground attack, reconnaissance, and air defense missions with stealth capability.

We offer different models for this product!

Also available in FRP composite construction; Model# FSC-F35-C-01

Also available in a 24" height adjustable steel construction; Model# FAI-F35-S-02

The F35 Wrap Around Maintenance Stand system with rolling stairway and stand-alone engine stand is used for the Lockheed Martin F-35 aircraft. This is a custom project and may be built to be compatible with any aircraft. All of our Wrap Around Maintenance Stands are proudly manufactured in the USA.

Features:

| • OSHA compliant guardrails, mid-rails and toe-boards | • Lockable storage box |

| • Optional utilities to include air, electrical and lighting | • Leveling and stabilizing jacks |

| • Heavy duty 12” swivel casters with brakes and swivel locks | • Modular and light weight design |

| • Ample under stand space for personnel access and equipment storage | • Dimensions: 108"Max, 96" Mid, 84" Min |

| • Articulating stairways, casters with parking brakes, unique vertical jacking system | • Designed-for-purpose non-slip decking on platforms |

| • Six lightweight steel work stands that form a convenient maintenance docking system | |

• Turnkey maintenance stand solutions include the design, engineering, fabrication, installation and training.

• All products evolve from end-user perspective from initial design through entire life cycle product and support.

• Unique designs working with steel or aluminum and 3D modeling.

PRODUCT SPECIFICATIONS:

BENEFITS:

Fall Prevention

Guardrails in compliance with OSHA requirements are included around all open edges of the working platform. The top of the guardrails on the top platform are 42 inches above the top deck with a proper mid-rail, and can sustain 200 lb. lateral loading forces for safety. Four-inch high toe-boards are also provided. We also offer safety orange powder coating and metal mesh screening on all three sides, half height.

Platform Height Adjustability

Ganged jacks allow for raising and lowering the platform while enhancing the user experience by allowing the operator to adjust the platform height infinitely without the need for a fork lift. The jack is designed to provide low cost, ridged, mechanically synchronized jacking free of unwanted movement. Our proprietary “puck” system ensures the telescoping tubes are always centered with zero deviation. All parts and components are precision laser cut and CNC machined to tight tolerances.

The jacks utilize a single point drive system which can be operated at low rpm using a standard drill motor and hex fitting. Single point drive system components include differential gear drives (qty. 3 or 4 pending option selection), multiple couplings, pillow blocks, drive shaft tubing and mounting brackets.

Mobility

The stand can be moved/transported in two ways. The stand is mounted on heavy duty 12” swivel casters with polyurethane wheels. Swivel locks (90 degree increments), full face wheel brakes, and toe guard options are included. The casters allow easy positioning by personnel around the aircraft. A hinged tow bar may also provided for moving with machine.

Optional air and electrical utility stations are available upon request. Two utility panels per stand would include four QD air ports, and a GFI protected duplex receptacle each. Individual receptacles are GFI protected, and it assumed incoming power is regulated at source. Source power and source air would need to be brought to the base of stand (Air hose reels and/or SOW cord with plug are available for additional quoting if required).

Optional lighting is available. Standard 4’ enclosed fluorescent fixtures with clear polycarbonate lenses. Uses (2) 54W T5HO lamps. A quantity of 4 lights would be mounted horizontally on an upwards angle on mounting brackets and hung on guardrails. Requires source power at the base of the stand.

Documentation

The following documentation will be provided at the completion of the project.

• All MSDS documentation for all coating processes and hazardous materials.

• A Certificate of Conformance (COC) for each stand signed by our QA representative.

• Two hard-copy sets of operation and maintenance manuals will be provided.

• Operation and maintenance manuals will also be provided in electronic format.

O&M manuals will include:

o Safety Hazards and Cautions

o Correct Operating Procedures

o Recommended Preventative Maintenance Schedule

o Suggested Spare Parts

Shipping and Delivery

Shipping in the form of a dedicated flatbed with tarps to protect from road grime in transit may be priced as an individual line item. Customers can opt to take care of their own freight collect.

Also available in FRP composite construction!!!

Composites offer several advantages; they are much more environmentally responsible, more effective and resourceful than traditional non-renewable material. Composites are non-magnetic, non-sparking, corrosion resistant, slip resistant, lightweight for reduced freight & install costs, impact resistant, fire-retardant and non-conductive for either heat or electricity.

Fabrication Authorities International can custom fabricate virtually any type of Aviation Work Platform. Our expertise includes in-house research and development, fully integrated manufacturing and an extensive materials line. With years of design, engineering and manufacturing experience, our dedicated staff can assist you from concept to completion in a timely fashion. All of our ladders are made in the USA and meet OSHA and ANSI 3124 standards.

Please call for additional options or custom designs.

Fabrication Authorities International, LLC. Is your new “total access” solution.

We can customize most Industrial Maintenance Platforms to your specific needs.

Please call (877) 324-9990 or (727) 324-4620 or (727) FAI-INC-0.

Fax us your request at (888) 909-6780.

Email us at sales@industrial-platforms.com